In today’s world, the quality of air plays a pivotal role in both our health and the performance of various systems. High-performance air filters are designed to enhance air quality by effectively removing airborne particles, allergens, and pollutants. This technological advancement not only contributes to cleaner environments but also significantly impacts the efficiency of systems that rely on clean air.

Efficiency is a critical factor in numerous applications, ranging from industrial operations to residential HVAC systems. An efficient air filter can reduce energy consumption by ensuring that air flows smoothly through the system, thereby decreasing the workload on fans and compressors. By minimizing resistance, high-performance air filters allow for optimal airflow, which is essential for maintaining the desired temperature and reducing operational costs.

Moreover, the implementation of advanced air filters can lead to improved overall system longevity. By capturing contaminants before they can cause damage, these filters protect sensitive components within various systems, enhancing their lifespan and reducing the frequency of maintenance. Understanding the relationship between air quality and efficiency is essential for both consumers and industries invested in sustainable practices.

High-Performance Air Filters: Their Impact on Efficiency

High-performance air filters are essential components in various applications, including HVAC systems, automotive engines, and industrial machinery. Their primary role is to enhance air quality while optimizing efficiency. Below are key aspects of how these filters influence overall performance:

- Filtration Efficiency: High-performance filters are designed to capture a higher percentage of airborne particles, including dust, pollen, and microorganisms. This increased filtration efficiency leads to cleaner air, which is vital for both health and equipment performance.

- Energy Consumption: By maintaining a clean airflow, these filters reduce the workload on fans and pumps. As a result, systems require less energy to circulate air, leading to lower energy bills and reduced environmental impact.

- Longevity of Equipment: Clean air filters prevent particles from entering machinery, which can cause wear and tear. By using high-performance filters, organizations can extend the lifespan of their equipment, ultimately decreasing maintenance costs and downtime.

- Improved Airflow: High-performance filters are engineered to provide optimal airflow without compromising filtration efficiency. This balance ensures that HVAC systems or engines can operate effectively, reducing the risk of overheating and improving overall performance.

- Environmental Compliance: Many industries face strict regulations regarding air quality and emissions. Utilizing high-performance air filters helps businesses meet these standards, contributing to sustainability efforts and enhancing corporate responsibility.

In summary, the adoption of high-performance air filters significantly impacts efficiency across various systems. By improving air quality, reducing energy consumption, prolonging equipment life, and ensuring regulatory compliance, these filters play a crucial role in maintaining optimal operational performance.

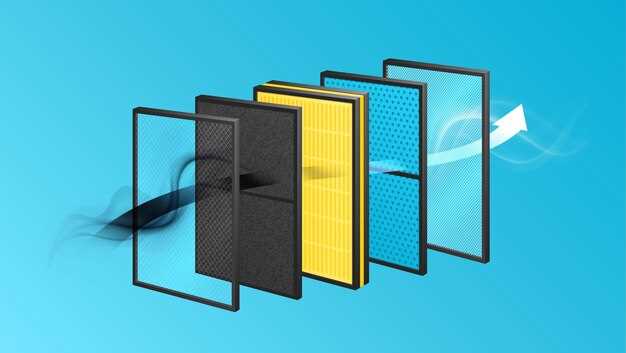

Understanding Airflow Dynamics in High-Performance Filters

High-performance air filters are designed to optimize airflow while capturing contaminants effectively. Understanding airflow dynamics in these filters is crucial for enhancing system efficiency and performance. The capacity of an air filter to manage airflow is influenced by its design, material, and structure.

The principle of airflow dynamics involves the movement of air through various filter media. High-performance filters utilize advanced materials that increase surface area and enhance particle capture efficiency. This allows for smoother airflow patterns, reducing turbulence and resistance.

Airflow can be quantified using two primary parameters: air velocity and volumetric flow rate. Air velocity refers to the speed at which air moves through the filter, while volumetric flow rate indicates the total amount of air passing through the filter within a given time frame. Understanding these parameters helps in designing filters that maintain required airflow levels without compromising filtration efficiency.

| Parameter | Description |

|---|---|

| Air Velocity | The speed of air movement through the filter, affecting pressure drop and efficiency. |

| Volumetric Flow Rate | The total volume of air passing through the filter over time, essential for system performance. |

| Pressure Drop | The resistance encountered by airflow as it passes through the filter, influencing performance. |

| Filtration Efficiency | The ability of a filter to capture particles while maintaining optimal airflow. |

Filters with lower pressure drops allow for higher airflow rates, which can enhance system efficiency. However, this must be balanced against the need for effective filtration. The choice of filter media plays a critical role in this balance. Techniques such as pleating, layering, and using electrostatically charged materials can improve airflow while enhancing particulate retention.

In summary, a thorough understanding of airflow dynamics in high-performance filters is essential for maximizing operational efficiency. By optimizing parameters like air velocity, volumetric flow rate, and pressure drop, filter designs can achieve both superior filtration and effective airflow management.

Comparative Analysis of Filter Materials and Their Impact on Performance

When evaluating high-performance air filters, the choice of filter material plays a crucial role in determining overall efficiency. Various materials exhibit different levels of air permeability, filtration efficiency, and durability, which ultimately influence their performance in various applications.

Fiberglass Filters are one of the most commonly used materials in air filtration. These filters are effective at trapping larger particles, making them suitable for residential uses. However, their performance tends to diminish over time as dust accumulates, resulting in reduced airflow and efficiency.

Pleated Polyester Filters offer a significant upgrade over fiberglass options. The pleated design increases the surface area, allowing them to capture smaller particles with higher efficiency. This type of material is typically more durable and maintains consistent airflow for a longer duration, thus enhancing overall performance in air systems.

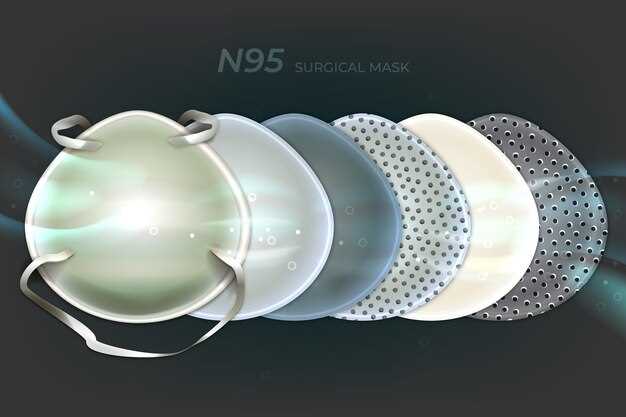

HEPA Filters, or High-Efficiency Particulate Air filters, are designed to capture at least 99.97% of particles that are 0.3 microns in size. The materials used in HEPA filters, such as layered fiberglass or synthetic media, provide superior filtration. Although they may restrict airflow slightly more than other types, the trade-off is often worth it, especially in environments requiring superior air quality.

Activated Carbon Filters primarily target odors and volatile organic compounds (VOCs) rather than particulate matter. They are often used in conjunction with other filter types to enhance air quality. The porous nature of activated carbon allows it to adsorb various pollutants, making it a valuable addition to air filtration systems aimed at improving overall performance.

Electrostatic Filters utilize static electricity to attract and trap particles. Made from charged synthetic materials, these filters can capture a larger variety of contaminants, including small particles. Their self-charging properties enable them to maintain effectiveness longer, thus providing a higher performance level without frequent replacements.

In summary, the selection of air filter material significantly impacts performance. Fiberglass filters serve basic needs, while pleated polyester, HEPA, activated carbon, and electrostatic options provide advancements in filtration efficiency. Understanding these differences allows consumers to make informed decisions that enhance the efficiency and effectiveness of their air filtration systems.

Key Factors in Choosing the Right Air Filter for Your System

Selecting the appropriate air filter is crucial for optimizing the performance and efficiency of your HVAC system. Several key factors should guide your decision-making process.

Firstly, the filter’s MERV rating, which stands for Minimum Efficiency Reporting Value, is essential. This rating indicates the filter’s ability to capture airborne particles. A higher MERV rating signifies better filtration, but it may also lead to increased airflow resistance. Balancing filtration efficiency and airflow is critical for maintaining system performance.

Secondly, consider the type of filter media used. Common materials include fiberglass, pleated polyester, and HEPA. Each type offers distinct advantages, such as enhanced particle capture or improved lifespan. Selecting the right media aligns with your specific air quality requirements.

Thirdly, dimension and fit are vital. Filters must match the size and configuration of your HVAC system to function efficiently. An improperly sized filter can lead to bypass airflow, reducing its effectiveness and potentially damaging your system.

Additionally, evaluate the filter’s lifespan and maintenance needs. Some filters require more frequent changes than others, which can impact overall costs and convenience. Choosing a filter with a longer life may reduce maintenance frequency, but it is essential to ensure that it still meets your air quality standards.

Finally, consider any specific environmental concerns or needs, such as allergies or sensitivity to pollutants. Specialized filters, such as those with activated carbon or antimicrobial properties, can significantly improve indoor air quality in such cases.

How High-Performance Filters Improve Engine and HVAC Functionality

High-performance air filters play a critical role in enhancing the functionality of both engines and HVAC systems. These filters are designed to optimize airflow while effectively trapping contaminants, resulting in improved efficiency and longevity.

In engine applications, high-performance filters contribute to better combustion and power output. By facilitating a cleaner air supply, these filters enable the engine to operate more effectively. The benefits include:

- Increased Horsepower: Enhanced airflow allows for a more efficient combustion process, leading to increased horsepower.

- Improved Fuel Efficiency: Cleaner air intake results in a more efficient fuel-air mixture, optimizing fuel consumption.

- Reduced Emissions: By ensuring complete combustion, high-performance filters help minimize harmful exhaust emissions.

Similarly, in HVAC systems, high-performance air filters significantly improve indoor air quality while enhancing system functionality. Their advantages are manifold:

- Enhanced Air Quality: These filters capture smaller particles, allergens, and pollutants, ensuring cleaner air circulation.

- Energy Efficiency: With less restriction to airflow, HVAC systems can operate more efficiently, leading to reduced energy consumption.

- Extended Equipment Lifespan: By preventing dust and debris buildup, high-performance filters help maintain system integrity and prolong equipment life.

In conclusion, high-performance filters are essential for optimizing the functionality of both engines and HVAC systems. Through improved airflow, enhanced efficiency, and better air quality, these filters contribute significantly to overall performance and reliability.

Maintenance Requirements for Sustaining Filter Performance

To ensure optimal performance of high-performance air filters, regular maintenance is essential. This involves periodic inspection of filters to identify any accumulation of particulates that could impede airflow. A clear filter promotes efficient operation, enhancing the overall effectiveness of the air filtration system.

Cleaning and replacement schedules should be established based on the specific environmental conditions and operational demands. For instance, filters used in dust-prone locations may require more frequent cleaning or changing compared to those in cleaner environments. It’s crucial to follow the manufacturer’s guidelines regarding the lifespan and maintenance frequency of the filters.

Inspecting the sealing around filters is another vital maintenance task. Gaps or improper installation can lead to unfiltered air bypassing the filter, severely affecting performance. Ensuring a tight seal guarantees that maximum airflow passes through the filter while minimizing contamination.

Additionally, monitoring airflow rates can provide insights into filter performance. A drop in airflow may indicate blockage or filter saturation, signaling the need for immediate attention. Utilizing tools such as differential pressure gauges can effectively measure airflow changes and assist in timely maintenance actions.

Finally, any performance enhancements can be further supported by maintaining surrounding components, such as fans and ducts, which also impact overall efficiency. Regular maintenance of these systems, alongside air filters, creates a synergistic effect that sustains optimal airflow and filtration performance over time.

Real-World Case Studies: Performance Gains from Upgrading Filters

Numerous industries have recognized the significant impact of upgrading air filters on operational efficiency. One notable case is a manufacturing facility that replaced its standard fiberglass filters with high-efficiency particulate air (HEPA) filters. This transition resulted in a marked reduction in airborne contaminants, enhancing product quality and reducing waste. As a result, production downtime decreased by 20%, leading to an overall increase in output.

In the healthcare sector, a hospital implemented pleated air filters with a higher MERV rating to improve indoor air quality. This upgrade not only eliminated harmful pathogens but also resulted in a 30% decrease in energy consumption for HVAC systems. The improved air circulation contributed to a healthier environment for patients and staff, showcasing the dual benefits of efficiency and health.

A data center also serves as a compelling example of the advantages of filter enhancement. By shifting from traditional filters to high-performance options, the facility achieved better cooling efficiency. This upgrade reduced the load on cooling units by 15%, resulting in significant energy savings and improved performance stability for critical IT infrastructure.

Similarly, a large commercial building adopted advanced air filters to address issues related to particulate matter and allergens. The upgrade not only improved tenant satisfaction but also led to a 25% increase in HVAC system efficiency. This change underscored the direct correlation between air quality management and energy performance.

These case studies illustrate that upgrading air filters is an effective strategy for enhancing operational efficiency across various sectors. The measurable performance gains underscore the importance of investing in high-quality air filtration systems to achieve both environmental and economic benefits.